Our Products

Advanced Technology

Cutting-edge engineering for superior performance, efficiency, and reliability in air and pollution control.

Tailored Solutions

Customized designs to meet specific needs, ensuring optimal functionality and client satisfaction.

Industry-leading Capacity

Robust equipment with high capacity and pressure capabilities for demanding industrial applications.

PRODUCT RANGE

IAEC specializes in the engineering of advanced composite structures designed to withstand significant structural loads and meet high safety standards, making them perfect for critical infrastructure applications. Our portfolio includes high-performance composite components like scrubbers, pickling tanks, and blowers. These products are renowned for their durability, with a proven track record of exceptional service life extending beyond 60 years.

BLOWERS

IAEC Centrifugal Fans & Exhausters are based on drawings obtained from USA.

Type : K/HPK – radial

Drive – Direct drive blower , v belt drive blower and coupling drive blower.

Features: *High effeciency upto 75% Minimum maintenance *Adjustable discharge *Easy installation *Dynamically balanced impeller.

Application: Dust collection, ID Fans, Pneumatic Conveying, etc.

Range: Capacity – upto 3,50,000 m3/hr Pressure – upto 1000 mm wg.

SPE type blower These are available in two types -1) Long Shaving Wheel 2) Wool Wheel.

Application: Pneumatic Conveying of long fibers, wool, cotton, rayon, trimming of metals, etc.

Range: Capacity – upto 90,000 m3/hr , Pressure – upto 400 mm wg.

DRY TYPE DUST COLLECTION SYSTEM (PULSE JET FILTERS)

The Pulse Jet Filters Type is rigidly constructed with the cleaning of bags carried out by high-pressure compressed air. Filters are fabricated in modular construction. The sequence of the operation of the Solenoid valves is controlled by a solid-state timer.

Features: * Can withstand high negative pressure because of rigid construction. * Inspection & maintenance of filter bags can be carried out from clean air side without entering dirty air chamber, thus the maintenance man can work under clean working conditions. * Identification of the damaged filter bags and changing of these can be carried out in no time compared to other filters * Modular construction as a result the entire bag house need not be shut for maintenance.

Application: Chemical & Processes industries, Cement & Power Plants, Sand & Shot Blasting Machines, Foundries etc.

Range: Capacity upto 4,30,000 m3/hr.

FORCED DRAUGHT COOLER (F D COOLER)

The F D Cooler is an air-to-air heat exchanger. It contains with bank/banks of tubes placed vertically (now a day) and hot gas is passed through the inside of the tubes. Fans usually axial flow is employed to supply ambient air which passed outside the tubes. Generally in industries, forced draft cooler is used for heat exchange primarily because of the advantage of less power consumption.

Features: *Upto 200 digree C temperature reduce *High efficiency *Heavy dust particles removal *Less power consumption *Operated at high temperature.

Application: Ferro Alloy Plants, DRI Plants etc.

Range: Upto 10,00,000 Am3/hr.

FUME EXTRACTION SYSTEM

IAEC (Calcutta) Pvt. Ltd. offers a solution for every application, especially for Steel plants, Captive power plants, and other industries. We design, manufacture & supply the complete system including all pairs of fume extraction systems with your specifications and requirements. We offer optimized technical solutions.

Features: *Upto <30 mg/m3 or less emition *High durability *Low power consumption *The Collection efficienty is very high even for small particles *Can handle large gas volume, heavy dust loads at low pressure.

Application: Production plants for steel melting shop, Ferro alloy plant and other industries. Iron & steel production(ore processing, blast furnaces, converters).

Range: Upto 1,00,000 m3/hr.

CYCLONE

Cyclonic action to separate dust particles from the gas stream. In a typical cyclone, the dust gas stream enters at an angle and is spun rapidly. The centrifugal force created by the circular flow throws the dust particles toward the cyclone’s wall. After striking the wall, these particles fall into a hopper located underneath.

Features: *High efficiency, *Long Service Life, *Low operating & maintenance cost.

Type: Single and Double cells.

Range: Capacity – upto 1,50,000 m3/hr.

SCRUBBERS

This equipment is used to purify exhaust gas through its internal special filling pieces which enlarge the surface between exhaust gas and fluids. The entire Pollution Control System consists of the following equipment and components.

– Scrubbers

– Centrifugal Exhaust Blowers

– Fume Collection Hoods

– Ducts

– Chimney

Material of construction: FRP moulded & filament wound using lsopthalic, Bisphenol, Epoxy Resin – PP & HDPE Spiral Wound – PP/FRP, SS304, PVC/FRP, CPVC/FRP, PVDF/FRP, FEP/FRP.

Packed bed Scrubbers are packed with Hollow Thermoplasic elements such as dumped razing rings or poll rings which are fluidized by the ascending gas stream as it passes counter current to the descending scrubbing liquid. Removes soluble gases like HCL, Cl2, Br2 and NH3, SO2/ SO3, H2S & NOx.

Application: Chemical Plants, battery industry, chemical plating shop etc.1

Range: Upto 1,00,000 m3/hr.

WET TYPE DUST COLLECTION SYSTEM (VENTURI SCRUBBER)

A venturi scrubber is designed to effectively use the energy from the inlet gas stream to atomize the liquid being used to scrub the gas stream. This type of technology is a part of the group of air pollution controls collectively referred to as wet scrubbers.

A venturi scrubber consists of three sections: a converging section, a throat section, and a diverging section. The inlet gas stream enters the converging

section and, as the area decreases, gas velocity increases (in accordance with the Bernoulli equation). Liquid is introduced either at the throat or at the entrance to the converging section. The inlet gas, forced to move at extremely high velocities in the small throat section, shears the liquid from its walls, producing an enormous number of very tiny droplets. Particle and gas removal occur in the diverging section as the inlet gas stream mixes with the fog of tiny liquid droplets. The inlet stream then exits through the diverging section, where it is forced to slow down. Venturis can be used to collect both particulate and gaseous pollutants, but they are more effective in removing particles than gaseous pollutants.

Features: *Upto 0.1 micron particles* High efficiency * Rugged construction *Removal of fine fumes * Operated at elevated temperature.

Application: Foundries, Chemical Plants Crushers, Power Plants etc.

Range: Upto 1,00,000 m3/hr.

AXIAL FLOW FAN

IAEC heavy duty Industrial Exhaust Fan consists of Cast Aluminium variable pitch type Impeller mounted on motor shaft or EN8 Shaft driven by V belt drive.

Type: Tube Axial – Man Circtilators – Man Cooler.

Range: Capacity – upto 2,00,000 m3/hr Pressure- upto 150mm wg.

Applications: Exchange heat through environmental air, Cooling Towers, Air-Cooled Condensers and Air-Cooled Heat Exchangers are typical applications.

CENTRIFUGAL BLOWER

IAEC Centrifugal Fans & Exhausters are based on drawings and software obtained from M/s. Rotamill Gmbh, Germany. Blade Type: Aerofoil, Backward curve and partially radial bladed. Drive – Direct drive blower, v belt drive blower and coupling drive blower. IAEC Centrifugal Fans & Exhausters are known as ‘RO’ 15/25/35/50/75.

Feature: *High efficiency upto 90%* Minimum maintenance * Adjustable Discharge * Easy installation. * Dynamically balanced impeller * Software to design bigger fans than the standard available. Application: Ventilation, Dust Collection. Air Conditioning, Oil, Gas, Coal, Biogases, Wood & Husk Fired Boilers, Fluidised Bed Boilers, ID Fans. Industrial Burners, Pneumatic Conveying etc.

Range: Capacity – upto 3,00,000 m3/hr Pressure – upto 2500 mmWG. Single.

DOUBLE INLET DOUBLE WIDTH (DIDW)

High efficiency (up to 82%) allows for high savings in electricity consumption and low noise. For a fan, the noise source is mainly the air turbulence created by the impeller. This series fan has been created to obtain the lowest noise thanks to the aerodynamic profile of the inlet cone and the static and dynamic balancing of the impeller.

Application: Suitable for the supply air for the various applications of the ventilation, air- conditioning and processes industry.

Range: Volume: from 1000 m3/h up to 1,00,000 m3/h , Pressure: from 20 mm wgp up to 400 mm wg.

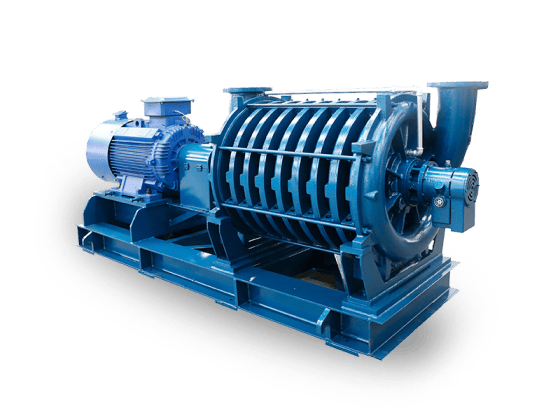

MULTISTAGE CENTRIFUGAL BLOWERS

IAEC Multistage Centrifugal Blower consists of several Aluminium alloy impellers mounted on EN-8/S.S. Steel shaft running in cast iron/cast Aluminium body. Stage – up to 9 nos.

Features: *Delivery of oil free air / gas *Surge proof type and therefore no overloading *No internal lubrication *High efficiency *Easy installation *Dynamically Balanced impeller *Rugged Body.

Application: Pneumatic Conveying, Bio-gas boosting, Glass blowing, Agitation of liquids, Sewage disposal, Ore flotation, Air Scouring of Pressure filters.

On-Site Balancing Service

On-Site Balancing Servicehelps to you in providing a practically efficient method for test facilities, assembly & plant maintenance. This service is delivered without dismantling the machine thereby minimizing the down time, labor cost as well as production loss.

Advantage of On Site Balancing –

* Saving operation of your machine from going in breakdown state

* Saves electricity power of your drive motors of all the equipments

* Saves you’re dismantling and re-assembly time & money for balancing

* High accuracy achieved as total assy. balancing is done at its operating rpm and in its own operating

environment, bearing housing & structure.

* Saves your transport, follow-up, production loss, down time, break down loss

* Increase performance of machines

* Minimize vibration sound.

REVERSE JET FILTER UNIT

The range of reverse jet filter units is designed to cater to more specialist dust that cannot be handled by the standard shaker-type filter systems. Reverse jet/reverse pulse units are normally required where a constant air volume is needed without the possibility of the equipment being shut off for cleaning.

Features: *High efficiency, *Long Service Life, *Low operating & maintenance cost.

Type: Single and Double cells.

Range: Capacity – upto 1,50,000 m3/hr.

IAEC BEND & REBEND TESTING MACHINE (UP TO 200 TON)

THE MACHINE SERVES TO CONDUCT BENDING AND FOLDING TEST, AS WELL AS TO CONDUCT BENDING TEST UNDER INDIAN STANDARD NO. ISO:1599.

IAEC Bending & Folding Machines are working with the following Steel Companies:-

1) Lloyds Steel Industries Ltd., Wardha … 1 no. 50 ton.

2) Jindal Vijayanagar Steel Limited … 1 no. 50 ton.

3) Tata Iron & Steel Co. Limited … 1 no. 25 ton.

4) Jindal Steel & Power Ltd., Raigarh … 1 no. 100 ton.

5) Tata Steel Limited … 1 no. 200 ton

6) Bokaro Steel Plant … 2 no. 25 ton

7) Durgapur Steel Plant … 1 no. 100 ton

The Machine Consists Essentially Of The Following Main Parts :-

Base Frame With Cylinder Is Build Up With Upper Top Frame By 4 Nos. Guide Pillars.The Cylinder Contains The Working Piston On Which Is Mounted The Bending Sliding Frame. The Bending Blocks With Rollers Are Adjustable By Means Of Lead Screws Which Is Electrical Operated By Geared Motors And

Manually By Hand Whill.

The Interchangeable Bending Punches Are Fixed In Upper Top Frame By Means Of Links. The Machine Is

Provided With Thrust Plates For Conducting Compression Tests In General And Rebend Tests In Particular. The Upper Thrust Plate Is Fitted In The Upper Top Frame, The Lower Thrust Plate On A Special

Thrust Block On The Bending Table.

Control Panel For Press Operation, Indication Lamp, Volt Meter, Ameter, On / Off Main Switch And

Additional Operating Console, Etc.

Power Pack Consists Of Control Pump, Oil Tank and Adjustable Pressure Relief Valve, Pressure Gauge With Isolator, Air Cooler Etc.

Application: Weld Specimens, Sheet Plate, Rails Wires and Strips, TMT Bars As well As for Tempered

Specimens testing purpose.

get quotation

To receive a personalized quotation, kindly provide us with some details using the form.